Notification Center

Florian Einböck

Sep 24, 2025 | 6 min read

The railway industry is under increasing pressure to achieve greater efficiency, higher availability, and more sustainable operations. Increasing passenger demand, shrinking budgets, climate targets and the shortage of skilled personnel all highlight the same imperative: railways must embrace digitalisation.

Digital technologies promise smarter use of resources, predictive maintenance, and centralised management of complex infrastructure. Yet the full potential of railway digitalisation can only be realised if the connection between central systems and field elements becomes more flexible, secure, and standardised. This is precisely where Object Controllers come in.

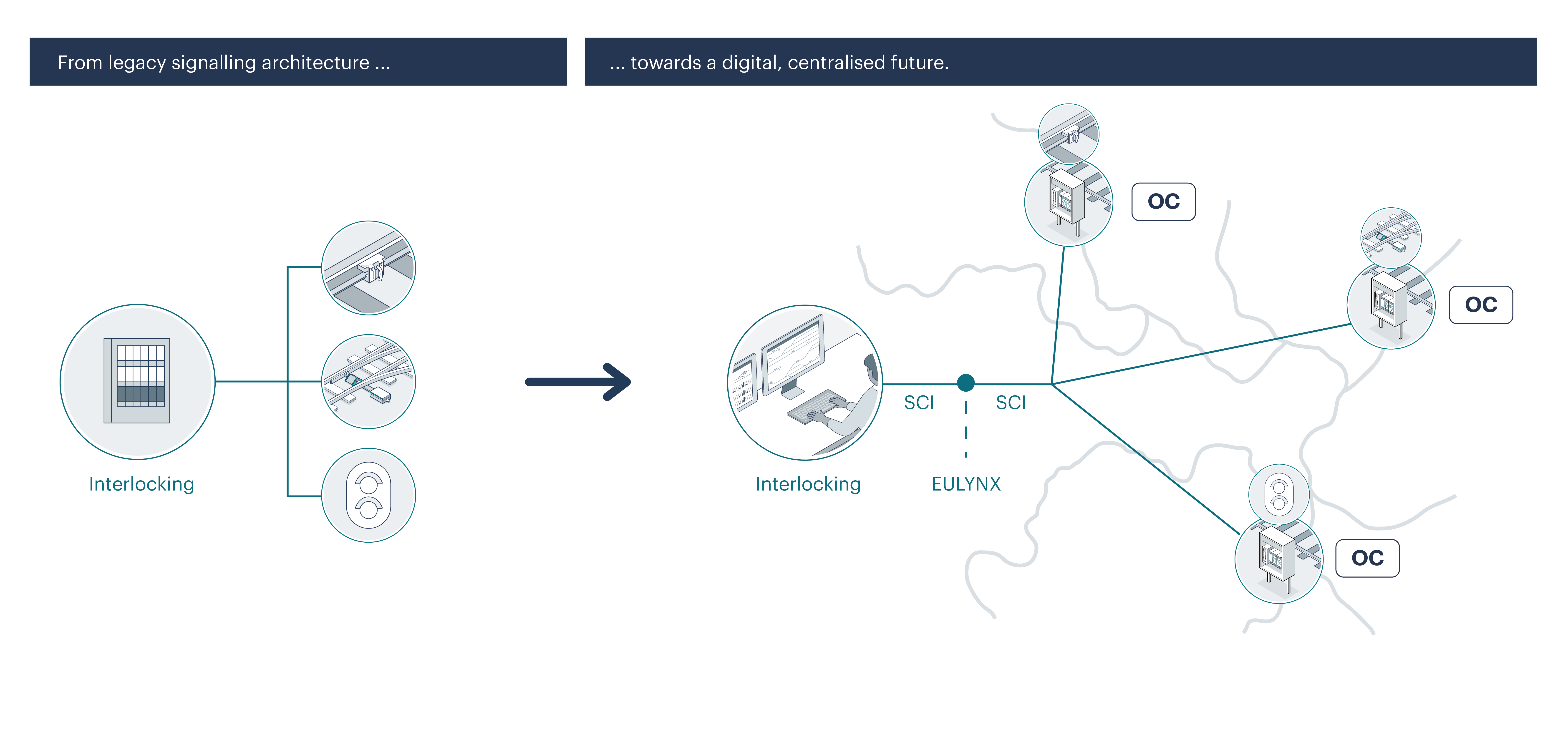

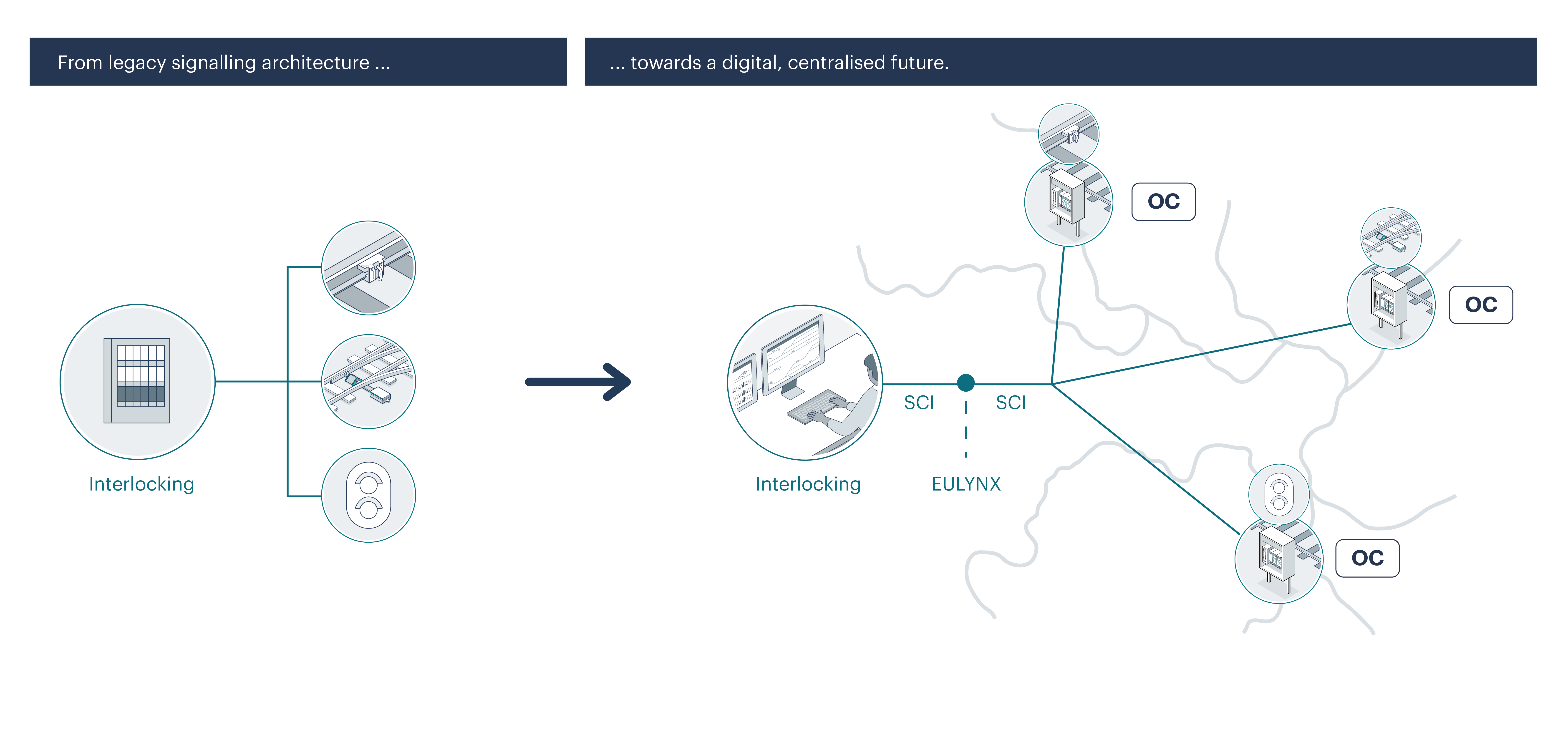

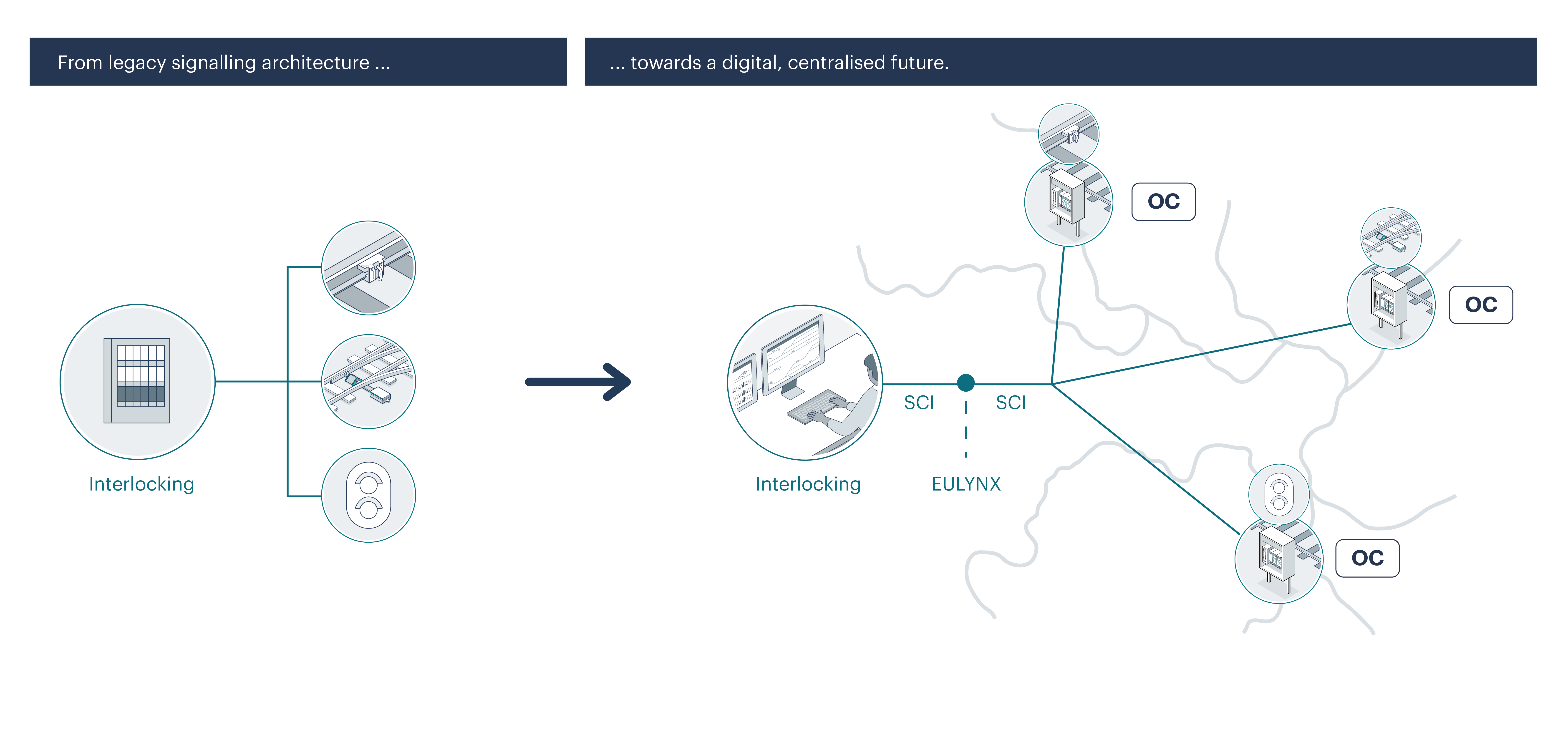

Most railway signalling installations today – both legacy and newly deployed systems – still follow a centralised approach. Interlockings and associated control and detection devices are located close to the field elements, such as point machines, track sections or light signals. Additionally, the hardware and software of these systems are linked via proprietary interfaces. A significant number of relay-based interlockings are still in operation worldwide, and in some regions new relay systems continue to be installed. This further reinforces the dependence on proprietary, tightly coupled architectures.

This legacy approach limits functionality and scalability, demands extensive cabling, and involves high installation effort and cost, while providing minimal data for monitoring or predictive maintenance purposes. It is also prone to wiring errors, insulation faults or even theft exposure. However, unlocking useful operational data depends on the digitalisation of railways to enable more efficient, reliable and future-proof operations.

Centralising interlocking functions in data centres is widely recognised as one of the most effective ways to improve efficiency and digitalisation in railway operations. Object Controllers are the key enabler of this transition, acting as the digital link between interlockings and field elements. By eliminating the traditional and limited control distance, Object Controllers allow operators to decouple hardware from location constraints, reduce the need for infrastructure and space, and simplify the local system design by reducing complexity. This makes centralised digital architectures more scalable, efficient, and easier to maintain. At the same time, it allows the lifecycle of the different signalling subsystems to be managed independently.

Standardised interfaces and protocols such as EULYNX or RaSTA are key enablers of a interoperable and future-ready signalling system. The adoption of standardised sub-system interaction ensures that digital interlockings and Object Controllers can communicate seamlessly, regardless of the manufacturer.

This reduces vendor lock-in and allows operators to source components based on performance and project-specific requirements. While the specifications define the required behaviour, suppliers remain free to innovate in their technical design. This directs development efforts from proprietary interfaces towards operational value, such as

higher performance,

easier usability and

lower lifecycle costs.

Furthermore, the use of standardised interfaces between interlockings, Object Controllers, and field elements decouples the life cycles of these components. Most importantly, it allows upgrades of subsystems to be carried out independently. This is particularly valuable in the context of resignalling and migration projects, as it facilitates stepwise digitalisation without disrupting the overall system. Such flexibility is essential for ensuring long-term scalability and efficiency.

Traditional maintenance strategies, which rely heavily on reactive interventions and on-site work, are becoming increasingly unsustainable. Rising system complexity, a shortage of skilled personnel, and higher expectations for system availability are making reactive approaches less feasible. To meet these challenges, operators will need concepts that make better use of data and digitalisation.

Object Controllers now provide real-time diagnostic data, enabling to collect data for condition-based and predictive maintenance. Operators can monitor key performance indicators, such as point switching times or environmental metrics, across the network. This data-driven approach replaces reactive interventions with proactive planning, reducing downtime and optimising the deployment of resources.

An additional advantage of Object Controllers is their remote access capability. They enable operators to securely collect diagnostic data and deploy software updates from central locations. The vision is to perform routine maintenance largely remotely in the future, reducing the need for on-site visits. This significantly reduces the need for extensive on-site work, making maintenance processes more efficient, predictable, and scalable.

Digital interlockings and modern Object Controllers unlock the full potential of signalling systems and redefine the possibilities of modern railway signalling. Thanks to their higher safety, lower costs, improved scalability and real-time intelligence, they form the foundation of a resilient and future-ready rail infrastructure. Operators that adopt this approach position themselves to meet the growing demands of capacity, sustainability and operational excellence.

Share this post

Object Controllers

Would you like to know how you can drive forward digitalisation in your railway operations with modern object controllers?

Share this post

Object Controllers

Would you like to know how you can drive forward digitalisation in your railway operations with modern object controllers?