Notification Center

Train DetectionUnited States of America

Frauscher Track Vacancy System FTVS Testing

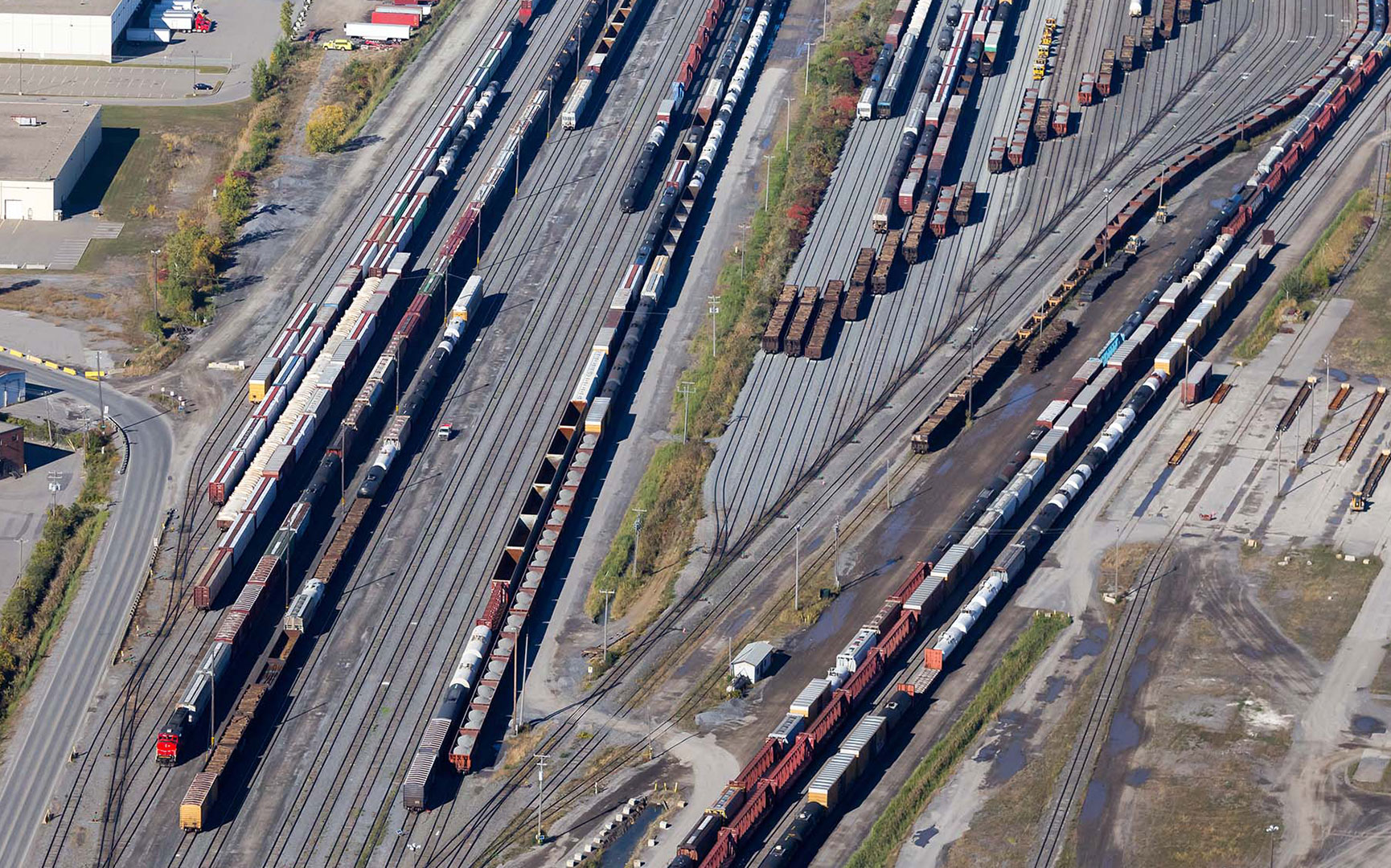

During the initial development phase of the Frauscher Track Vacancy System FTVS, a number of pre-production units were released for real-world testing to examine their performance in typical yard environments. Consequently, several trials were conducted in the United States.

The Frauscher Track Vacancy System FTVS was developed as a cost-effective axle counting solution for non-vital applications. During its initial development phase, several pre-production units were tested in real-world environments to assess their overall performance in various yard settings – to this end, a number of trials were conducted in the United States.

The trials aimed to evaluate not only the system’s performance but also its ease of installation and maintenance, as well as its ability to integrate seamlessly into existing yard infrastructure.

One of the trial installations, conducted from October 2022 to March 2023, involved installing three Frauscher Wheel Sensors RSR110 at a yard switch and connecting them to the FTVS. Monitored regularly by Frauscher engineers, the system handled an average of 30 vehicles and 3600 axles daily without any miscounts, resets, or equipment failures. The quick and convenient installation of the wheel sensors was facilitated by the patented Frauscher rail claw, which eliminated the need for drilling into the rail. Due to the faultless performance of the FTVS, the trial was deemed as a success, and the railroad operator decided to move the FTVS equipment from this yard and reinstall it in a different yard. The system is now operational in the second yard, where the operator aims to verify and replicate the impressive results observed at the original location.

Simple architecture

The Frauscher Track Vacancy System FTVS features simple architecture with just three key components, making its installation very easy and convenient. Due to the limited number of components, the FTVS can also be installed in tight spaces.

High degree of flexibility

The FTVS is a highly flexible system that can be used for a wide variety of non-vital railway applications, including switch point protection in yards.

Exhaustive technical service

Frauscher offers not only high-performance solutions but also comprehensive technology guidance and on-site training.

This might also interest you

Train Detection, ServicesUnited Kingdom of Great Britain and Northern Ireland

Cutting delays through data-driven maintenance

Train DetectionIndia

Ensuring reliable rail operations across India´s longest rail-road bridge

Train DetectionFrance

Axle counting adds fail-safe control to laser diagnostics

Data TransmissionIndia

South Central Railway