Notification Center

Frauscher Products

Reliable products for a wide range of railway applications

All Frauscher products are known globally for their outstanding availability under all types of conditions. Ranging from robust and proven inductive wheel sensors to innovative axle counters and object controllers for switch points, as well as data transmission and connectivity managers: Frauscher products are designed to provide railway operators with all the data they need to increase their network’s efficiency and safety.

Wheel Sensors

Axle Counters

Point Control

Data Transmission

Frauscher Connect

Frauscher products offer exceptional quality

From sensor coils to fully equipped cubicles: Our development and production processes are certified according to IRIS and other standards, which ensures outstanding product quality. By utilizing customer protocols, our own safety protocol or via standard interfaces , our products can be implemented into any environment in an easy and convenient way. When it comes to both hardware and software development, the primary focus is the fullfillment of rail-specific requirements, particularly concerning safety, transparency, and availability.

During the production process, our wheel sensors and evaluation boards undergo various stages of development, which are subject to ongoing inspections. Positive findings are a prerequisite for the production process’s continuation, and all inspection procedures are recorded and stored in a database. These procedures allow Frauscher to ensure maximum traceability.

In addition, innovative working models guarantee strict adherence to schedules. A well-conceived logistics and planning system supports our employees in the timely completion of all orders through final assembly and shipping.

This might also interest you

Train DetectionUnited States of America

Frauscher Track Vacancy System FTVS Testing

Train DetectionAustria

GKB Graz-Köflacher Bahn

Train DetectionIndia

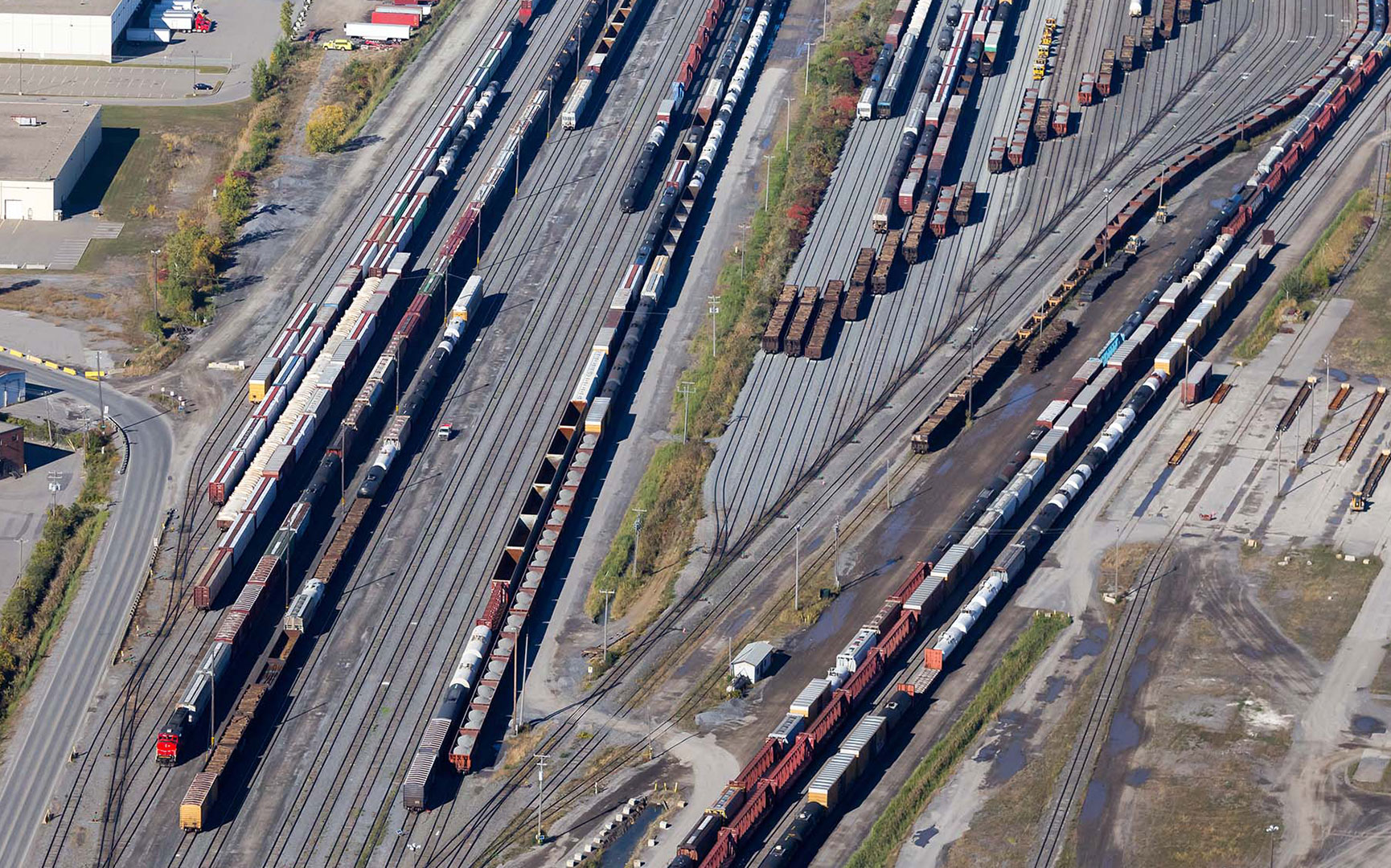

Increasing Availability at Adra Yard

Train DetectionFrance

Extension Line D Tram Bordeaux

Feel free to contact us anytime!

Do you require more information? Contact us - we're here for you!